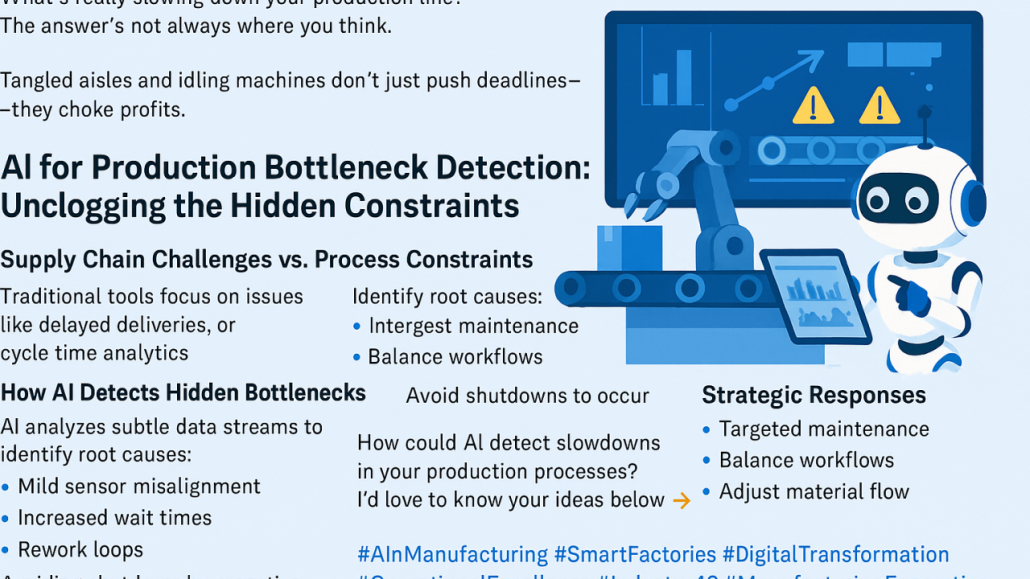

This image presents a clear and practical explanation

of how AI can identify hidden bottlenecks and inefficiencies in production and operational

environments—issues that often remain invisible when

relying on traditional monitoring tools. The visual

composition combines industrial elements, data

dashboards, and a friendly AI robot, symbolizing the

collaboration between human teams, machines, and

artificial intelligence. Rather than portraying AI as a

replacement for people, the image positions it as an

intelligent assistant that observes, analyzes, and

supports better decision-making.

At the core of the image is the idea that what slows

down production is not always obvious. Conveyor

belts, robotic arms, and dashboards represent modern

production systems that appear automated and efficient

on the surface. However, warning icons and

highlighted data points on the screens suggest that

problems can exist beneath this smooth exterior. The

text emphasizes that tangled workflows, idle machines,

or subtle process mismatches do not just delay

deadlines—they directly impact profitability. This

framing shifts the conversation from technical

optimization to business impact, making the message

relevant for both operational teams and decision-

makers.

The left side of the image explains the limitations of

traditional tools. Conventional analytics often focus on

visible symptoms such as delayed deliveries, missed

targets, or overall cycle times. While these indicators

show that something is wrong, they rarely explain why.

AI, by contrast, analyzes continuous data streams

across machines, sensors, workflows, and timing. It

can detect small but meaningful signals—slight sensor

misalignments, gradually increasing wait times

between steps, or repeated rework loops—that slowly

erode efficiency. These issues are easy to overlook

individually, but together they can choke throughput

and margins.

A key strength highlighted in the image is AI’s ability

to identify root causes rather than surface-level

problems. By correlating data across multiple systems,

AI can reveal how one small constraint affects the

entire process. This enables organizations to move

from reactive firefighting to proactive optimization.

Instead of responding only after a breakdown or major

delay, teams can address issues early, before they

escalate into shutdowns or lost revenue.

On the right side, the image focuses on action. AI

insights are translated into strategic responses such as

targeted maintenance, balancing workloads, and

adjusting material flow. This reinforces an important

point: AI analytics are only valuable if they lead to

practical decisions. The visual flow from detection to

response shows AI as a bridge between data and

execution, helping teams act with precision rather than

guesswork.

Overall, the image communicates a strong narrative

about modern operations. Complex systems generate

vast amounts of data, but insight does not emerge

automatically. AI serves as the layer that brings clarity,

uncovering hidden constraints and drop-offs that

humans alone might miss. By making inefficiencies

visible and actionable, AI helps organizations run

smoother operations, reduce waste, and protect profits.

The message is clear and grounded in reality: AI is not

about futuristic promises, but about solving real,

everyday problems that slow businesses down.